Milling of vertical and parallel planes with milling machine are often used in actual machining operations. It is necessary to understand and master the practical milling method.

1. Circular milling vertical plane

A vertical plane is a plane that is perpendicular to the reference plane. There are three ways to cut a vertical plane with a circular milling cutter.

(1) Milling is done with a flattened clamp on a horizontal milling machine

Clamp the vertical plane with a flattened clamp to fit the smaller workpiece.The main factors affecting the verticality of the following points: fixed jaw face and the work surface perpendicularity error. The datum does not fit tightly with the fixed jaws. Circular milling cutter has a large degree of cylindrical error. The flatness of the datum plane is large. Clamping force is too large and so on.

(2) In the horizontal milling machine with angle iron clamping for milling

Applicable to the workpiece surface is relatively wide and relatively narrow processing of the workpiece milling.

(3) Milling with an vertical mill cutter on a vertical milling machine

For the base width and long, narrow processing of the workpiece, you can use the end mill on the machine tool processing.

The main factors affecting the vertical degree are: vertical feed, the end of the cylindrical milling die error; horizontal feed, the end of the milling cutter cylindrical error, vertical milling head spindle axis and vertical feed direction of the vertical error Big.

2. Milling the parallel plane with a circular milling cutter

A parallel plane is a plane parallel to the reference plane. Milling the parallel surface with a circular milling cutter, usually in a horizontal milling machine with a flattened clamp clamp for milling. The main factors affecting the parallelism are: the base plane and the flat mouth clamp clamp body surface is not parallel; flat mouth clamp clamp body surface and milling machine table table is not parallel; cylindrical milling cutter cylindrical error and so on.

3. Milling the vertical and parallel planes with a face milling cutter

(1) vertical plane milling

1) with a flat clamp clamp, end milling vertical surface.

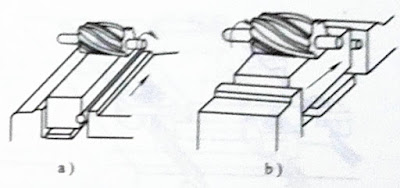

2) in the machine table on the table surface clamping, end milling vertical surface, as shown in the figure.

(2) parallel plane milling

1) Milling the parallel plane on the top of the vertical milling machine, as shown in the figure.

2) Milling the parallel plane at the top of the horizontal milling machine, as shown in the figure.

没有评论:

发表评论