Milling right angle grooves with milling machine generally has three kinds, namely slot, half-slot and closed groove. The right angle groove is mainly milled with a three-edge milling cutter and can be milled with an end mill and a keyway cutter. Half pass and closed grooves are milled with end mills or keyway milling cutters.

1. Use a three-edged cutter to cut the right angle groove

(1) Milling cutter selection

The width of the milling cutter L≦B; the diameter of the milling cutter D>d+2H. Where B is the groove width to be machined; d is the diameter of the cutter bar gasket; H is the groove depth, D, L is the cutter diameter and width.

(2) Workpiece clamping and correction

Under normal circumstances the use of flat clamp clamp workpiece. When the slot is slotted, the fixed jaws of the flat clamp should be perpendicular to the axis of the milling machine spindle.

(3) Commonly used tool setting method

1) Marking method. Draw the dimension line and position line of the right angle groove in the machining part of the workpiece.

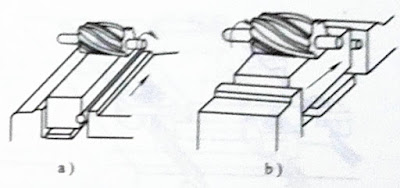

2) Sticker method is shown in figure.

In actual production, two methods are used in coordination.

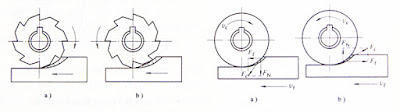

2. End milling cutter milling half-pass and closed groove

When using an end milling cutter to mill half a slot on a milling machine, select the end milling cutter diameter to be equal to or less than the width of the groove. Due to the poor rigidity of the end mill, milling is easy to produce "partial" phenomenon, the depth of the deep groove, the number of points should be milling to the required depth. Milling to the depth, then the two sides of the slot to the size of the milling. Expansion milling should avoid smooth milling, to prevent damage to the cutter and bite the workpiece.

When the milling cutter is closed with an end mill, it should be pre-drilled at one end of the groove before milling.

3. Use a keyway cutter to mill half-pass and closed groove

High precision, shallow depth of the half-pass and closed groove, can be used key milling cutter milling. The end face cutting edge of the keyway cutter can cut the workpiece when the milling machine is vertically fed. Therefore, it is not necessary to drill down the hole with the keyway cutter to cut through the closed groove.

4. Measurement of right angle grooves

The measurement of the length, width and depth of the right-angled groove generally uses the vernier caliper and the depth vernier caliper. Slot width limit gauge (key groove plug) check. The symmetry of the groove is tested with a vernier caliper or dial indicator.